|

LithomelT Company Ltd.

|

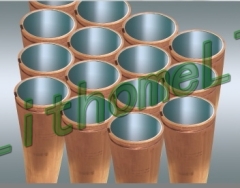

Copper mould tubes

| Price: | 300.0~3000.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Liaoning, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Copper mould tube is the heart of the continuous casting machine, the main function of the mould is to establish a solid shell sufficient in strength

opper mould tube is the heart of the continuous casting machine, the main function of the mould is to establish a solid shell sufficient in strength to support its liquid core upon entry into the secondary spray cooling zone. The mould is basically an open-ended box structure, containing a water-cooled inner lining fabricated from a high purity copper alloy. The inner face of the copper mould is often plated with chromium or nickel to provide a harder working surface, and to avoid copper pickup on the surface of the cast strand, which can otherwise facilitate surface cracks on the product. There are 3 different materials we can offer which covers a majority of the application around the world:

Phosphorous Deoxidized Copper(Cu DHP),

Silver Bearing Copper(Cu Ag),

Copper-Chromium-Zirconium(Cu-Cr-Zr)

Specification of copper mould tubes:

Section shape

Square Rectangular Round Beam Blank

Size range

60x60~500x500 100x240~300x500 Φ90-Φ500

Length 700-1000

Radius R4000-R16000

Coating Cr,Ni-Co-Cr

Please contact us for more information.

We produce and supply high quality copper mould tubes with hard chromium plating for continuous casting machines. We can simply provide this material for you according a drawing from your side or by ourselves designed. Welcome to your enquiry.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Copper Tubes

Mould Tubes

Copper Mould

Insulated Copper Tubes

Refrigerator Copper Tubes

Copper Plain Tubes

More>>